Cotton and shells. Ukraine's first steps towards gunpowder production

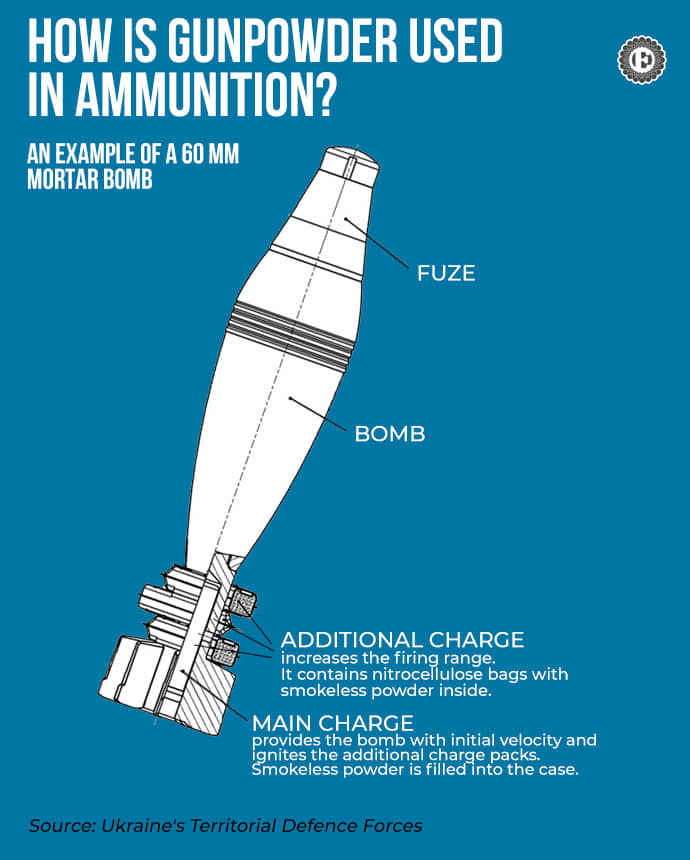

A single artillery round takes several kilograms of gunpowder to propel the projectile out of the barrel and provide it with the necessary velocity. The wars in Ukraine and the Middle East have caused the demand for ammunition to skyrocket and made propelling charges scarce on the market. Military-grade gunpowder is a highly complex product to manufacture, so it remains a critical bottleneck in the production of shells for both Russia and Ukraine, as well as their respective allies.

Prior to the full-scale Russian invasion, Kyiv had not established mass production of munitions and gunpowder, so it now has to work to compensate for this lost capacity. Gunpowder production starts with the cultivation of raw materials, such as wood and industrial hemp, but most commonly, Gossypium, the plant used to produce cotton. Ukraine last grew this crop in the mid-20th century, meaning that the entire process must now be relearned from the ground up.

Advertisement:The Ukrainian government has begun an experimental cotton cultivation project in Odesa Oblast, bringing in several foreign species of plant used to produce cotton.

It will soon become clear whether Ukrainian farmers can support the defence industry and whether Ukrainian factories can at least partially overcome the raw material shortage and ramp up ammunition production.

Gunpowder is a scarce commodity

For the first time since the Cold War, the West has remembered what mass production of ammunition is all about. Defence companies that previously produced tens of thousands of shells annually are now gearing up to supply hundreds of thousands. In the summer of 2024, Rheinmetall, one of Europe's leading ammunition manufacturers, secured its largest contract to date - EUR8.5 billion - for the supply of 155 mm shells.

At the same time, Western countries are chronically lagging behind production targets as companies face a shortage of explosives, primarily gunpowder. New production lines are being rolled out worldwide at gunpowder plants, though a shortage still persists. The race to produce ammunition is less about building more factories and more about securing the supply of scarce components.

The EU has recognised this urgency and established a EUR2 billion fund to support ammunition manufacturers, with 75% allocated for building powder plants and increasing the production of other explosives. With the help of subsidies and a large order, the EU aims to achieve a production capacity of 1.4 to 1.7 million artillery shells per year by the end of 2024. However, not all of these munitions will be sent to Ukraine; some will be exported or used to replenish domestic stockpiles.

Ukrainian companies are establishing their own production lines to narrow the gap with Russia in terms of ammunition produced, which sometimes amounts to several thousand shells per day. Ukrainian factories face the same problems of component shortages. Still, they do not have billions of dollars in subsidies to expand their supply base and are constantly being targeted by Russian forces.

Although Ukraine is making strides in producing certain items, mass production remains elusive. Ekonomichna Pravda has found that a major state-owned factory failed to fulfil a multi-billion-dollar contract with Ukraine's Defence Ministry for ammunition supply this year. If Ukraine had stable access to gunpowder and relevant state contracts, the number of shells produced would increase by hundreds of thousands annually, Vladyslav Belbas, Director of Ukrainian Armor, a company that produces artillery and mortar ammunition, told Ekonomichna Pravda.

He noted that the powders for NATO- and Soviet-calibre ammunition differ in both technology and properties. Most Ukrainian contracts require Soviet-quality gunpowder, which can only be sourced from countries in the former socialist camp and some states friendly to Russia through intermediaries. Plants are already operating at full capacity but are unable to supply gunpowder for purchase, as European munitions manufacturers have secured all available quotas until 2026.

"For us to be able to claim large volumes of gunpowder supplies, foreign producers demand that we contract their capacities for years to come. But we can't do that because the government gives domestic companies only one-year contracts instead of the promised three-year contracts. As a result, our planning horizon is much shorter than the supplier requires.

Which means we have to buy gunpowder from what remains on the market," Belbas explained.

Acquiring powder for the NATO-calibre ammunition is another challenge. Ukrainian Armor tried to buy it from an American company to adapt it to the Soviet-calibre munitions, but the deal never went through. The issue lies not only in the shortage of gunpowder but also in monopolisation of the market.

Many Western gunpowder plants are affiliated with companies that produce their own shells, prioritising the supply of this scarce component for their own operations. For instance, Eurenco, one of the largest gunpowder producers in Europe, is owned by the French government and is affiliated with the state-owned ammunition manufacturer KNDS France. Meanwhile, the controlling stake in Germany's Nitrochemie is held by Rheinmetall.

The 700-year-old powder plant in the Spanish city of Granada (FMG) is owned by the Slovak ammunition manufacturer MSM Group, while the American company Alliant Powder belongs to Vista Outdoor, a firearms manufacturer. An Ekonomichna Pravda source in the defence industry reported that the Ukrainian government is exploring several options for acquiring gunpowder. These options include obtaining explosives and other essential raw materials as aid from allies, pursuing joint production with European countries, and establishing its own production facilities.

Ukraine had failed to establish a full cycle of ammunition production and, accordingly, specific explosives by 2022. As a result, the decision was made to start with the basics - raw materials, specifically the cultivation of cotton.

How gunpowder is made

Not all gunpowder is suitable for use in munitions. For instance, black (smoky) gunpowder, which is made from charcoal, leaves behind 60% solid residue after combustion, making it heavy and inefficient.

This is why smokeless gunpowder has been the preferred choice for weapons for over a century. The formula for smokeless gunpowder is based on nitrocellulose, which can be produced by processing pulp from industrial hemp, cotton, and wood. Whereas hemp cellulose is suitable for short-range ammunition and shells, cotton powder is the best raw material for long-range artillery munitions due to its lightweight properties.

Vira Borovyk, a senior fellow at the Institute of Climate-Smart Agriculture at Ukraine's National Academy of Agrarian Sciences, explains that cotton fibre consists of 95% cellulose and 5% fat and other substances. First, the cotton is cleaned of the "remaining 5%", and pulp is obtained. The cellulose is then combined with sulphuric and nitric acid to produce nitrocellulose.

This nitrocellulose is subsequently mixed with other substances to create gunpowder pellets, which are dried and formed into propelling charges for ammunition.

Cotton experiment

Cotton is a plant that is not common to Ukrainian fields. It has the best yields in Central Asia, where the climate is much warmer. In Ukraine, cotton used to be grown in Crimea and across the region of Kherson.

But today, this plant is not grown on an industrial scale in the country. Why? "Cotton began to be grown in Ukraine in 1929 after being imported from Central Asia.

Government orders were primarily for military needs: thread for uniforms, wheels, cars, aeroplanes and parachutes. [Soviet leader Joseph] Stalin was bracing for war. The land was vast, and cotton was sown even where it couldn't ripen," says Borovyk. Cotton cultivation in Ukraine was curtailed after World War II due to much lower yields compared to Central Asia, where there was also a larger workforce available to harvest it by hand.

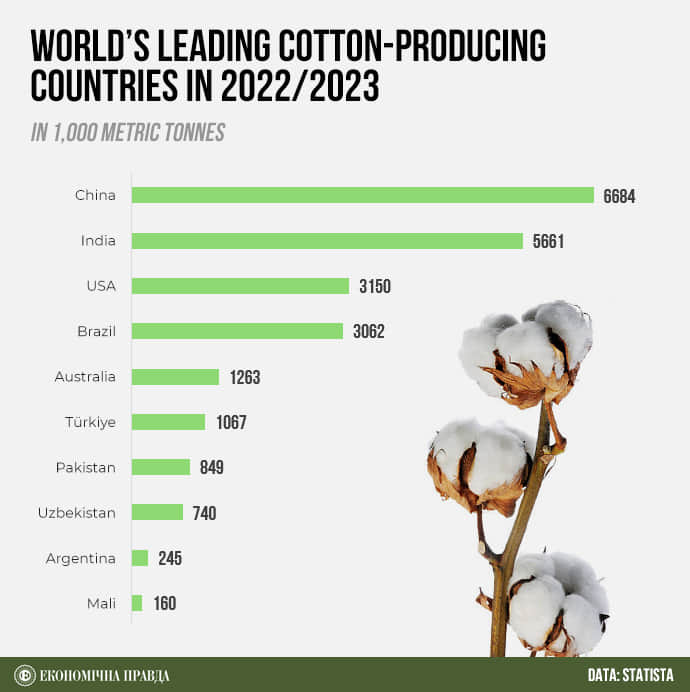

So during the Soviet era, cotton cultivation was moved to Uzbekistan and Kazakhstan. Over time, Ukraine developed its own cotton varieties with a short growing season (105-108 days), and Borovyk says 100% of these varieties have ripened successfully in Ukrainian conditions over the past 15 years. Nevertheless, the crop has not gained popularity on an industrial scale, primarily due to the lack of a market and the absence of companies that would process it into fibre for industrial use.

"There were small plots on farms, 2-5 hectares. I think the main reason why it didn't go further is that there was no interest in cotton, and it was easier to deliver fibre from Central Asia, which had a decent logistical network," explains Borovyk. As a result, cotton was not cultivated in Ukraine in the volumes needed for modern gunpowder production.

To revive the cultivation of this crop, the Verkhovna Rada (Ukrainian parliament) passed a bill in May 2024 to simplify the import of cotton varieties into Ukraine. Additionally, the government launched a pilot project to grow cotton in the country's south. "This experiment is necessary to understand whether cotton can grow there at all and whether it can be used for strategic industrial purposes.

We've seen that it can grow; there is a 99% chance it can," says Ihor Vishtak, Director of the Agricultural Development Office at Ukraine's Agrarian Policy Ministry. The test fields are situated in two locations within Odesa Oblast, which has a climate similar to that of Crimea. Currently, the volumes are modest, covering "several plots of 10 acres each," according to Vishtak.

Five imported varieties have been sown on these lands, as Ukrainian species were nearly wiped out by the Russians in Kherson before the full-scale invasion, leaving insufficient numbers for the experiment. "The Ruscists have destroyed a lot of our cotton," Borovyk recalls. "I managed to take out a small part of the collection, a few seeds, and now we're propagating our varieties. We'll continue to grow imported varieties until we do that." She expects that the Institute will be able to produce its own varieties for cultivation in two years.

The Agriculture Ministry has received interim results from the experiment: the first cotton bolls have formed and opened, indicating that the plant can ripen in the Ukrainian climate. The harvest will be collected in several stages to send the cotton at various ripening phases for testing in the laboratories of the Defence Ministry and the Strategic Industries Ministry. They will determine whether the fibre, which should be up to 0.15 mm long, is suitable for the production of gunpowder for long-range artillery munitions.

When to expect Ukrainian gunpowder

Growing cotton is an environmental experiment, not an industrial project.

Early estimates from the Ministry of Agrarian Policy suggest that cotton can theoretically be sown on 10,000 hectares in Ukraine. Despite the experiment's initial successes, it is too early to discuss mass cotton cultivation and business interests. Even if the experiment yields positive results, it does not necessarily indicate that large-scale crop cultivation would be advisable.

Firstly, growing cotton may not be profitable. Secondly, processing facilities will not materialise overnight. Thirdly, there is no assurance that the plant will thrive in other regions of the country.

Additionally, 2024 was characterised by an abnormal heatwave, which raises doubts about the likelihood of a successful harvest in the coming years. "This summer was scorching, which allowed the cotton to ripen under those conditions. We need to sow it for at least another year to make any forecasts regarding industrial-scale cultivation.

After that, we can conduct a more comprehensive experiment with larger sown areas and established practices. Only then will we be able to determine how the state and businesses should collaborate and who will purchase the raw materials," says Vishtak. Even if Ukraine gets its first decent cotton harvests, building the entire gunpowder production chain could cost hundreds of millions of dollars.

"Over the past three years, we've received only one proposal from a Western company to build a EUR20 million plant to process nitrocellulose into gunpowder. The proposal involved an annual output of 600 tonnes, enough to produce 160,000 rounds of 122 mm ammunition. But this is only one, the simplest stage in the production chain," said Belbas.

However, a gunpowder production facility is at significant risk of explosion if hit by Russian missiles, making it a vulnerable target for Russian strikes. Importing nitrocellulose from abroad also presents logistical challenges.

The German corporation Rheinmetall has announced plans to build an ammunition and gunpowder plant in Ukraine. However, the prospects for this project remain uncertain and will depend on the availability of orders and other conditions necessary to bring the project to fruition.

The construction of these plants could take several years. The production of components and raw materials for ammunition will remain an open niche in the global market for a long time. And it's not just the demand for shells but also the dependence on Chinese nitrocellulose.

European gunpowder plants import over 70% of their nitrocellulose from China, a close partner of Russia. This poses security risks and is making the EU think about restructuring its supply chains. Ukraine likely has the potential to produce gunpowder jointly with partners, at least in terms of its components.

But setting up its own full cycle of gunpowder production in sufficiently large volumes is a matter of many years and hundreds of millions of dollars in investment. If Ukraine wants to develop a robust and self-sufficient defence industry, access to critical components and raw materials will be one of the primary challenges it must address. Translation: Artem Yakymyshyn

Editing: Susan McDonald