British military receives first batch of spare parts made with 3D printer

30 November, 2024 Comparison of parts produced using different technologies. Photo from open sources Babcock company has handed over the first batch of spare parts made on a 3D printer to the British Army.

This was reported on the official Babcock LinkedIn page. The first batch of spare parts was delivered to the British Army under the TAMPA program and will be used to repair a significant amount of military equipment. Primarily, there is an active production of spare parts for L118 howitzers, which have been in use by the British Army for a long time and require constant maintenance and repair.

A British soldier observes the creation of a spare part.

A British soldier observes the creation of a spare part.

Photo credits: British Army

In addition, this project will produce spare parts for the Challenger 2 main battle tanks and other military equipment. This program aims to provide the UK Armed Forces with the ability to receive spare parts in a timely manner, reduce production costs, and deploy production anywhere in the country or during overseas operations. "The TAMPA project is a Ministry of Defense accelerator program aimed at progressively using additive manufacturing to increase the availability of materials in the defense system, overcome the problems of aging parts, reduce costs and improve productivity to strengthen defence capabilities and sustain critical assets," Babcock representatives explained in a statement.

In addition to the British Army, additive manufacturing of spare parts has been deployed to support the ship fleet, including Astute nuclear submarines and Type 23 anti-submarine frigates.

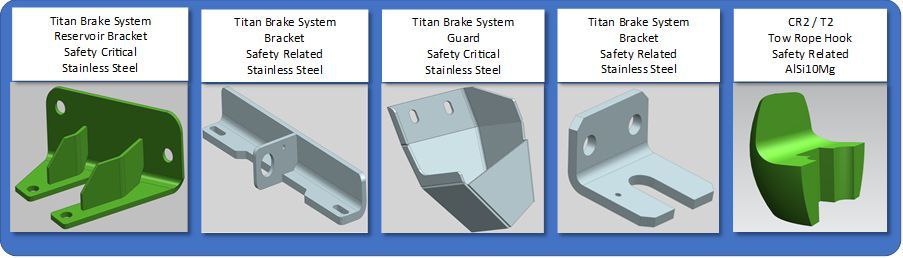

Spare parts under the TAMPA program for the Challenger 2 tank. Photo credits: RBSL

Spare parts under the TAMPA program for the Challenger 2 tank. Photo credits: RBSL

It should be noted that in addition to Babcock, the UK Ministry of Defense has signed contracts for the production of spare parts with NP Aerospace, RBSL, Thales, and AMFG. "It's been great to see the progress made by the Babcock team in the first phase of the TAMPA project.

Through collaboration with other project suppliers and the DE&S Delivery teams, Babcock has demonstrated that additive manufacturing can play a key role in improving the availability of defense parts," noted Charlotte Robinson, Head of the UK Strategic Command's Defense Innovation Group.

Earlier, Militarnyi reported that the private American company Ursa Major would start producing solid rocket engines by 3D printing at the request of the US Navy.

In September, the Pentagon allocated £12.5 million to Ursa Major to develop the company's engine manufacturing process using funds from the Office of Strategic Capital, an organization created to develop technology at the expense of private investors.